plastic boiler making

plastic boiler making

Our desire to develop plastic sheet metal work means that today our machinery can meet all your requirements, from design to the production of prototypes, but also series:

- Two flat saws: Semi-automatic cutting of plastics from 0.5 mm to 80 mm.

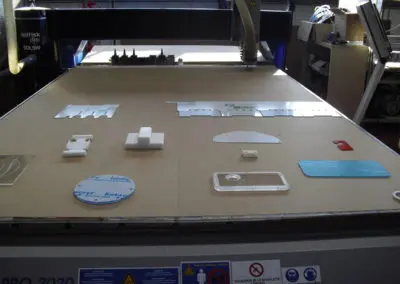

- A digital router (MecaPro 3020) with a machining capacity of 3000x2000mm with a thickness of 80mm according to your DXF drawings.

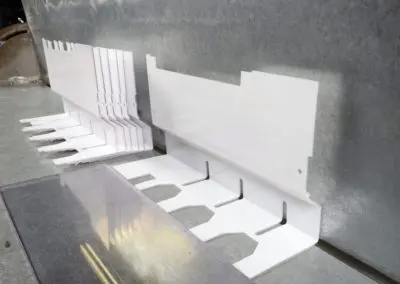

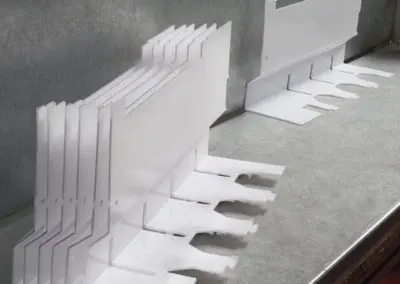

Two manual folding machines: "Multibi" for 1 to 4 instantaneous folds and "Shannon" for thin folds from 0.5 to 6mm

- A large assembly workshop

Our production capacity :

- Milling

- Drilling

- Sawing

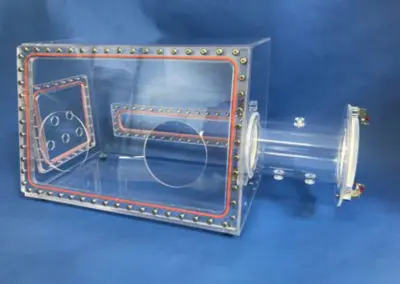

- UV and Silicone bonding

- Folding

- Shaping

- Hot bending

- Thermoforming

- Engraving and marking

- Plastic welding: extrusion, butt welding, etc. We have all the necessary machines.

We work with different materials:

- PMMA (Altuglas, Plexiglas, Perspex, Setacryl)

- Polycarbonate (Lexan, Makrolon)

- Polyethylene, Teflon, Cestidur, PA6

- PVC (Komadur, Trovidur, Forex, Komacel)

Areas of application :

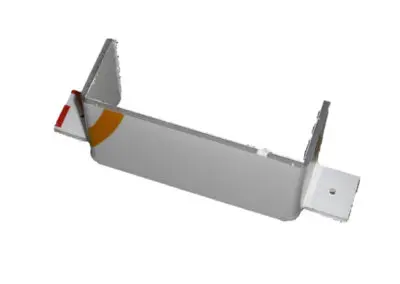

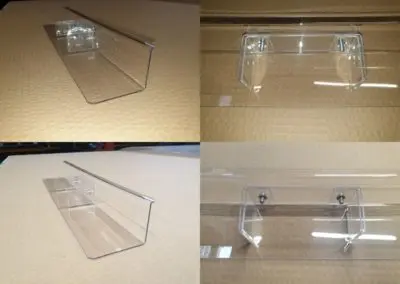

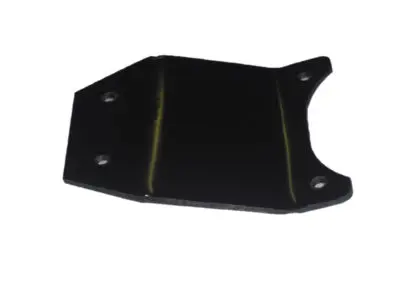

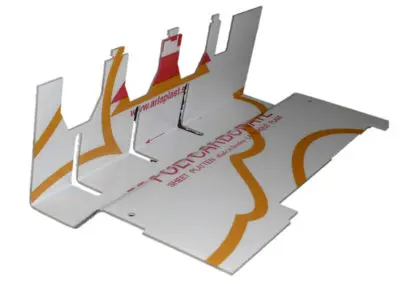

- Fairing and protective parts.

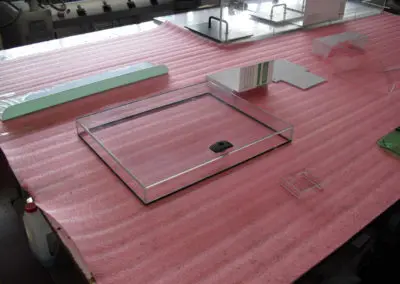

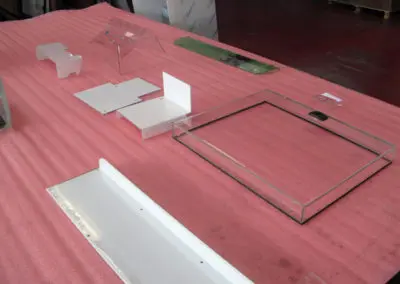

- Transparent or opaque protective covers

- Customised technical cases

- Retention bins and tanks,

- Food dispensers

- Technical cabinets

- Boxes and chests

- Transparent or opaque laboratory equipment

- Mechanical parts