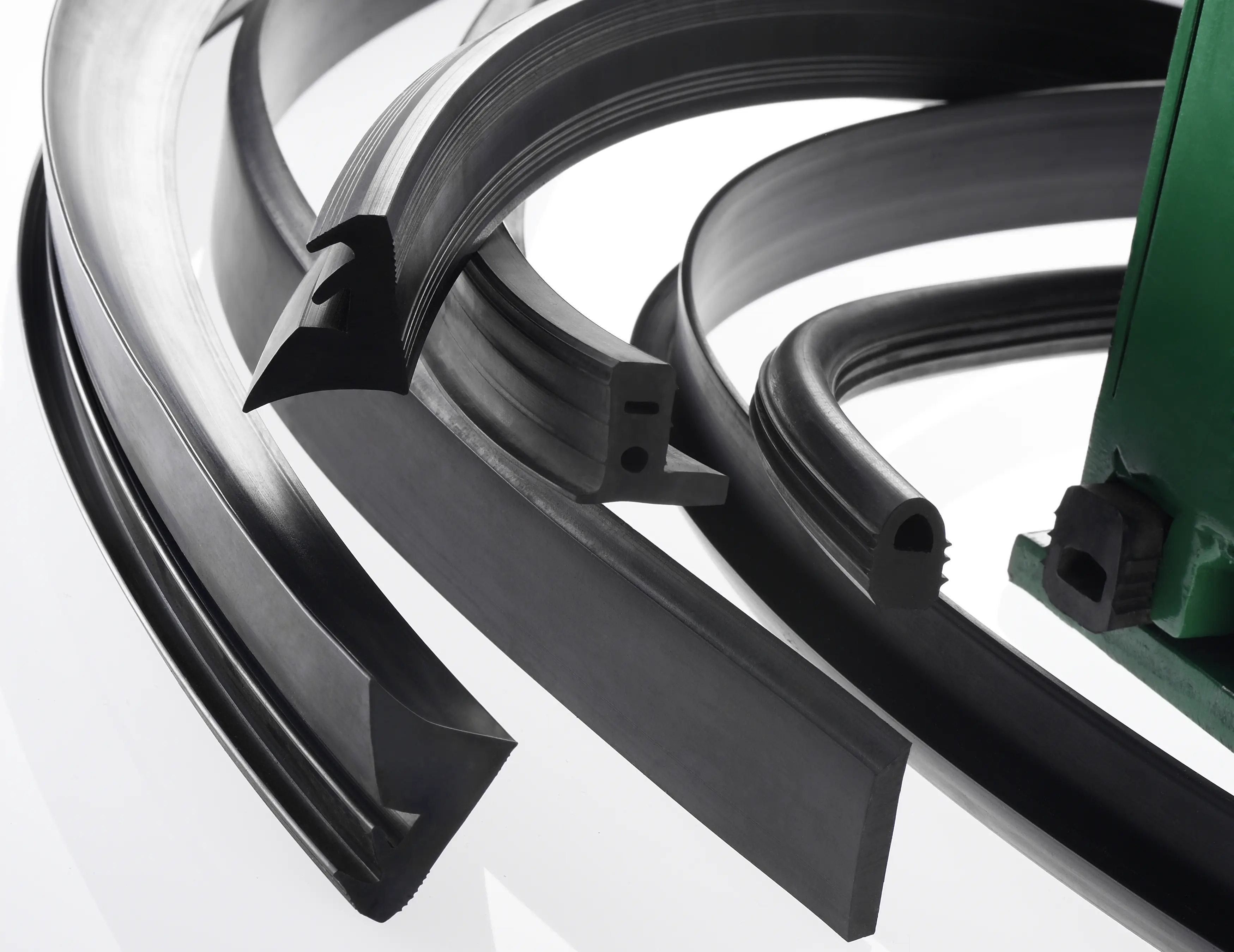

rubber extrusion

RUBBER extrusion

Since 1979 Askol has been the leading source for sealing rubber extrusions.

We are proud to manufacture our products in France and work hard to maintain our reputation forexcellence, innovation and reliability.

Our rubber extrusions and gaskets are not only highly accurate. They protect against sound, weather and vibration to create a durable joint you can trust.

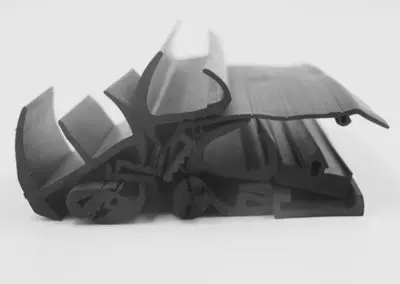

We offer several types of extrusions such as: co-extrusion (2 separate batches of compounds joined into one die), colour matching, plastic extrusion, sponge and cellular extrusions, and solid rubber profiles. These profiles can be supplied cut to length or cut and vulcanised (hot melt bonding) into endless joints or frame joints.

We use several compound formulas in accordance with different approvals, such as silicone, Neoprene, Nitrile, SBR, Viton, Fluorosilicone...

We also have :

- Develop a complete range of extruded rubber profile products in a wide variety of shapes and configurations to suit your exact requirements.

- The ability toanalyse your part in order to improve it to achieve a higher wear resistance over time.

- The possibility of reproducing an existing or new part, from a sample, a technical drawing...

Askol profiles are used for many functions including: window panes, garage doors, vehicle sunroofs, windscreens, tonneau covers, boat bonnets, other domestic and automotive applications.